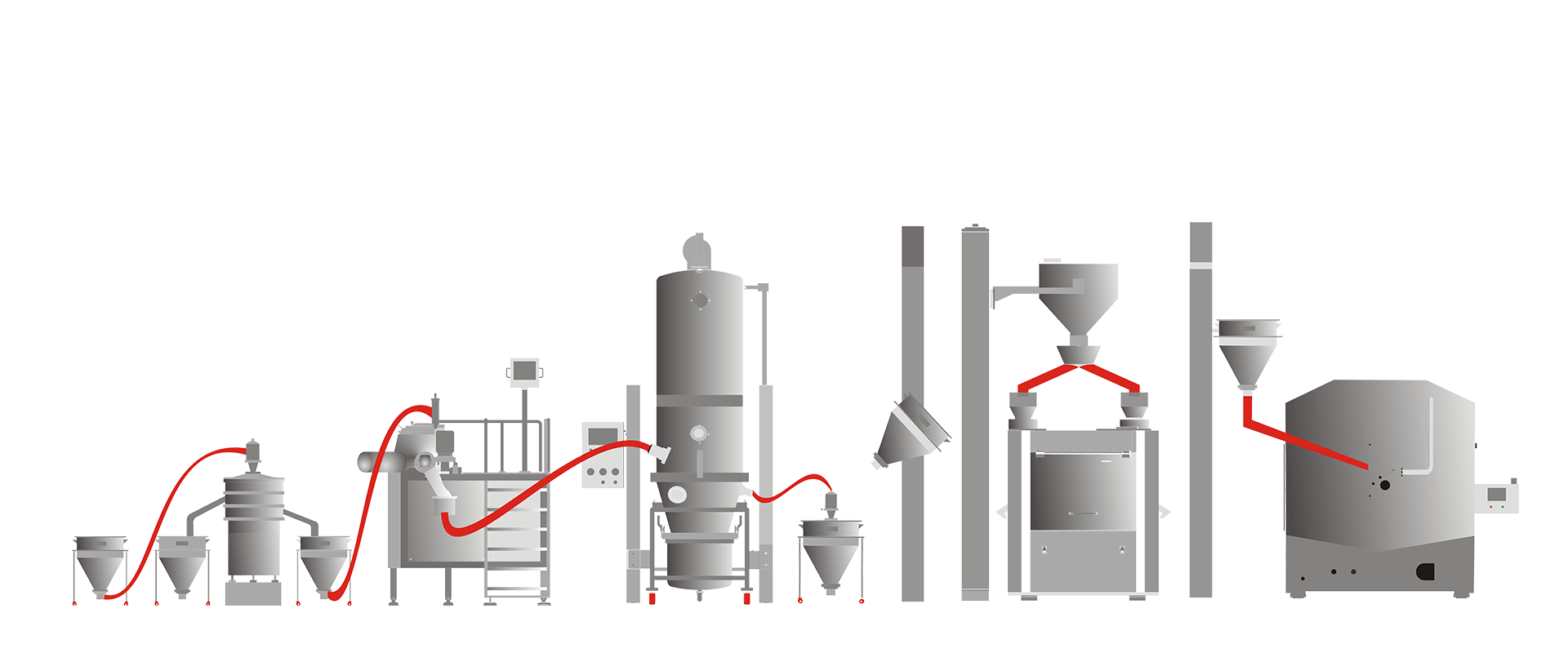

Close loop granulation suit

Integrated Granulation Line

Sifting, Milling, Loading, Mixing, Drying, Coating

Integrated Granulation Suit combines the process steps of mixing, granulating, and drying for the manufacturing of pharmaceutical granules. It is used for efficient operations thereby increasing productivity. Closed loop systems are minimising human interference and handling of material which results in reduction of manpower and material loss. The flow will be a vacuum transfer system or bin lifting system.

A pneumatic transfer pipe subsequently transfers the wet product to the fluid bed dryer, where it is dried through the inflow of the hot air distribution plate. At the end of the drying process, the product is emptied by a dry mill.

The process for manufacturing pharmaceutical granules begins by pneumatically filling the rapid mixer granulator. The mixing device which is driven from below, mixes and granulates the active ingredients and excipients. The Rapid Mixer Granulator is emptied via the integrated wet mill. Communication between mill and ensures that only as much product is emptied as the mill is able to process.

The whole process is done automatically with some operator intervention and the batch report in timely and objective manner according to cGMP and 21 CFR part 11.

Features & Advantages of close loop line

Introducing the revolutionary Close Loop Granulation Suit Integrated Granulation Line! Engineered with precision and unmatched quality, our product offers exceptional granulation results. With 15 years of industry experience, we provide the perfect solution for your granulation needs. Upgrade your manufacturing process today! .

- Maximum protection for the product and people

- Different bin with Blender used for multiple different IBC size

- Material Transferred by closed pneumatic transfer system

- Continuous process monitoring

- Easy operation

- Minimal manpower

- 12 inch HMI panel or PC for reports

- Meet with FDA/cGMP standard

- Increased yield and efficient

- WIP System for cleaning